Expanded Polystyrene (EPS)

Product Information

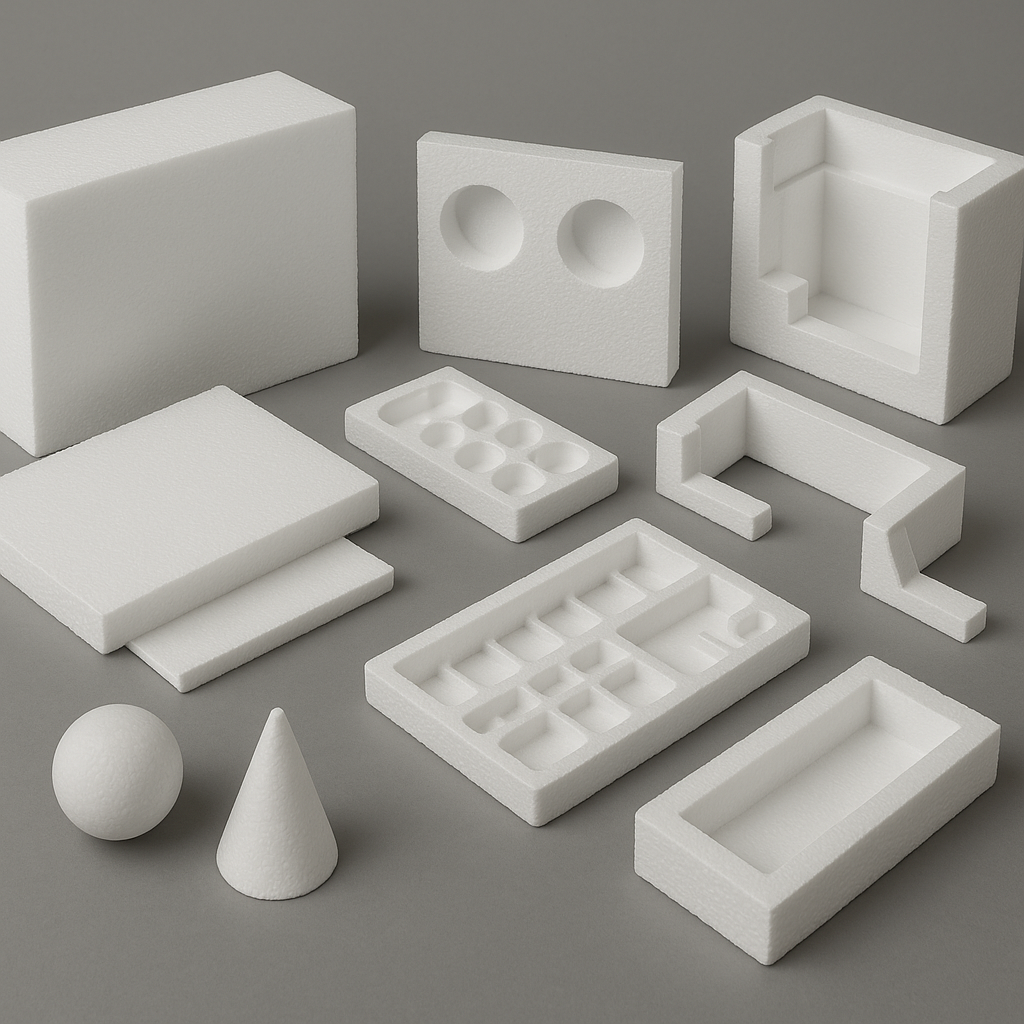

As EPS is made of 98% air, it is one of the lightest packaging materials in existence and therefore adds very little weight to packaging. This helps minimize transport costs and fuel emissions. It is also highly useful because it can be clearly marked with specific content like company logos, and labels can easily be attached directly to the packaging.

Applications of Expanded Polystyrene (EPS):

-

Packaging

Used for protecting fragile goods such as electronics, appliances, and pharmaceuticals. -

Thermal and Sound Insulation

Widely used in construction for insulating walls, roofs, and floors. -

Food Industry

Used for making disposable containers, such as food trays, cups, and packaging for fish or meat. -

Automotive Industry

Used in car bumpers and for protecting interior components due to its shock-absorbing properties. -

Model Making and Art Projects

Ideal for architectural models, crafts, and school projects due to its lightweight and easy-to-cut structure. -

Medical Packaging

Ensures safe transport of temperature-sensitive items like vaccines and medicines.

|

EPS |

|||

| Product | Application | Bead size |

DENSITY |

|

F1000 |

This particular grade is commonly utilized in demanding applications where structural integrity and insulation performance are critical. F1000 EPS finds extensive use in construction as insulation boards for walls, roofs, and floors, offering superior energy efficiency and moisture resistance. Additionally, it is employed in packaging solutions for delicate or high-value items, providing reliable cushioning and protection during transportation. Its high-density formulation makes it ideal for applications requiring robustness and longevity, such as in marine buoyancy aids and geofoam for civil engineering projects.

|

4.5 |

1.04 |

|

F2000 |

Represents a specialized grade of Expanded Polystyrene (EPS) renowned for its elevated density, thereby endowing it with exceptional strength, durability, and outstanding thermal insulation capabilities. Frequently deployed in applications demanding heightened structural integrity and superior insulation performance, F2000 EPS finds widespread usage in construction. It serves as a prime material for insulation boards employed in walls, roofs, and floors, offering unparalleled energy efficiency and moisture resistance. Furthermore, F2000 is a preferred choice in packaging solutions for safeguarding delicate or high-value items, ensuring reliable cushioning and protection throughout transportation. Its elevated density makes it especially suited for applications necessitating robustness and longevity, such as in marine buoyancy aids and geofoam utilized in various civil engineering projects.

|

4.5

|

1.04 |

|

F100 |

F100 is a specialized grade of Expanded Polystyrene (EPS) distinguished by its low-density composition, providing lightweight insulation with good thermal properties. This grade is commonly employed in applications where weight is a critical factor, such as in packaging solutions for fragile items where cushioning is essential but excessive weight is undesirable. F100 EPS is also utilized in lightweight construction projects where insulation is necessary but load-bearing capacity is not a primary concern, such as in decorative molding and temporary structures. Its low density makes it an economical choice for applications where structural strength is not the primary requirement, but thermal insulation and affordability are key considerations.

|

15 |

1.04 |

|

F200 |

Arty sheet, cups, trays, egg boxes, general packaging, vending cups, extruded profiles.

|

3.5 |

1.04 |